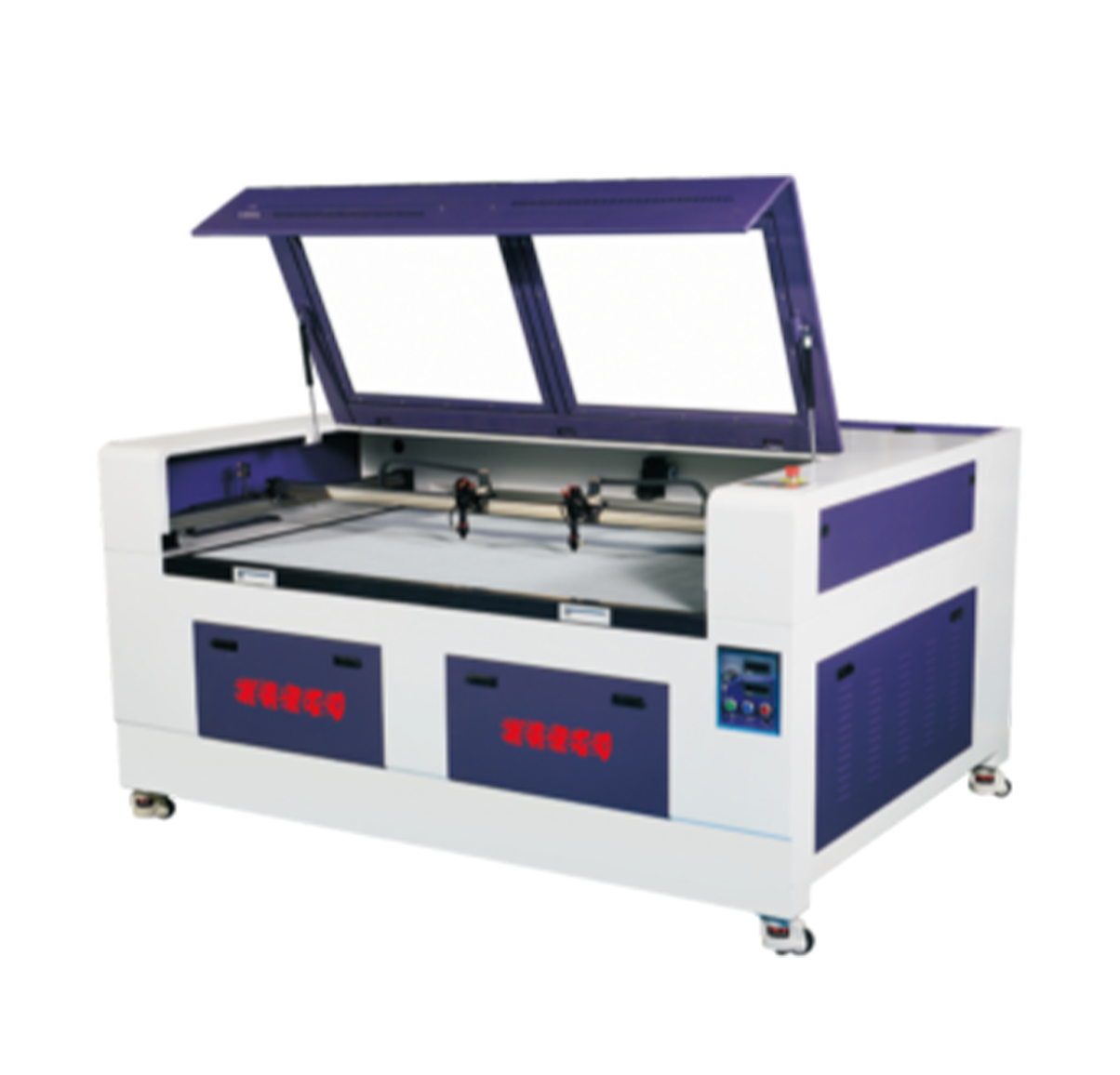

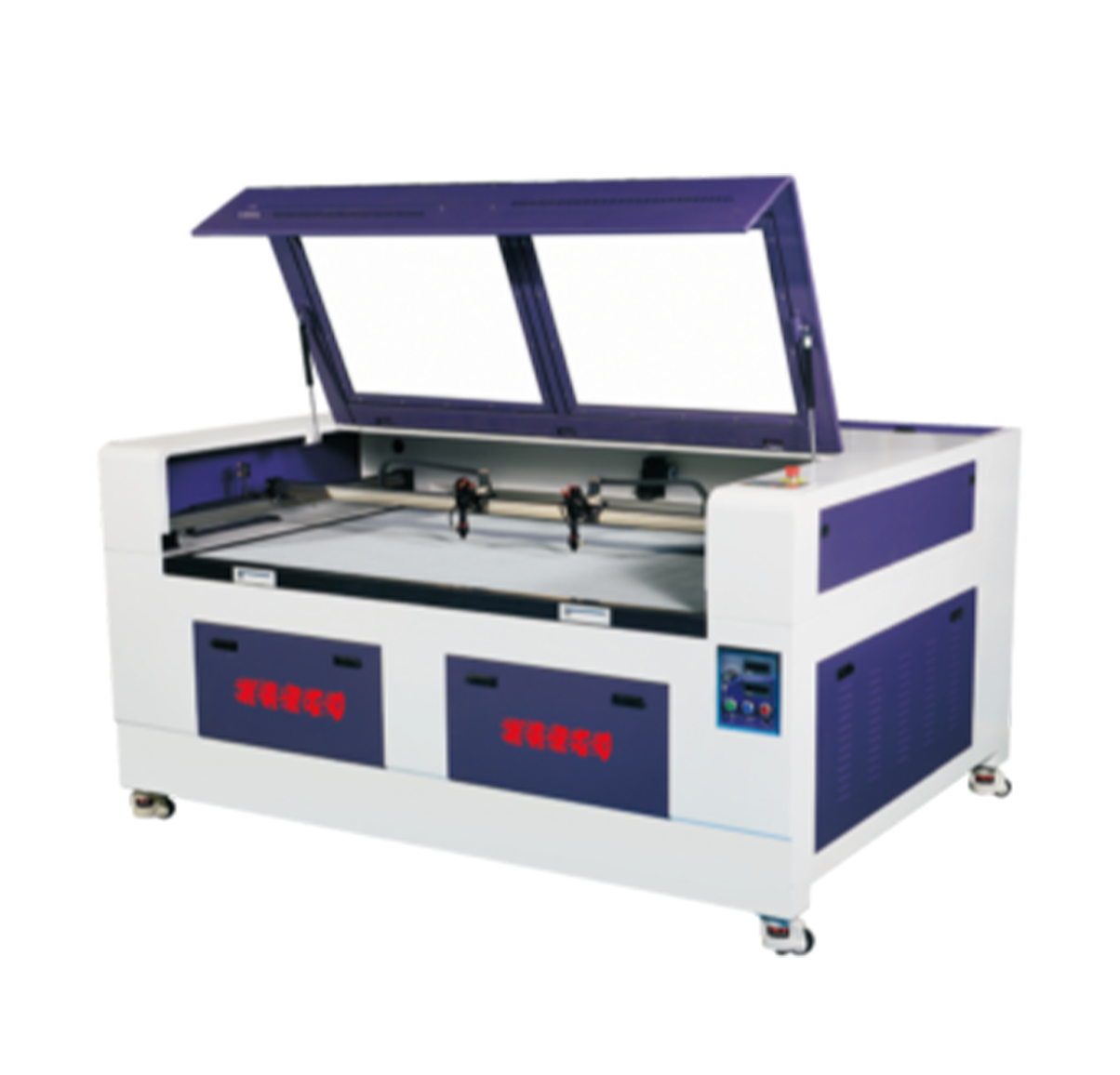

Non-metal material laser engraving and cutting machine -single-double heads series KR-1610D

Kargo Textile Apparel & Machines Ltd

Product Description:

The Non-Metal Material Laser Engraving and Cutting Machine KR-1610D is an advanced laser system designed for high-quality engraving and cutting of non-metal materials such as wood, acrylic, rubber, leather, and plastic. With both single and double-head configurations available, this machine offers flexibility for various production needs. The KR-1610D uses CO2 laser technology to deliver precise, intricate cuts and high-resolution engravings at impressive speeds. It is an ideal choice for industries such as signage, crafts, packaging, home decor, and advertising, offering superior performance for both small-scale and large-scale production.

Key Attributes:

- Single & Double-Head Options: Available in both single and dual-head versions, providing flexibility to accommodate different production volumes and material sizes. The dual-head version allows for simultaneous processing, increasing throughput.

- CO2 Laser Technology: Equipped with a CO2 laser tube, the KR-1610D ensures precise engraving and cutting on non-metal materials, delivering smooth edges and detailed designs.

- High Precision and Speed: This machine offers high-speed processing with fine, accurate engravings and cuts, making it ideal for both detailed small projects and larger production runs.

- Wide Material Compatibility: Capable of processing a wide range of non-metal materials, including wood, acrylic, plastic, leather, rubber, and fabric.

- Large Work Area: The KR-1610D offers a spacious working area (1600mm x 1000mm), suitable for handling larger workpieces or larger production batches.

- User-Friendly Interface: Designed with an intuitive control panel and software, the machine is easy to operate, making it suitable for both beginners and experienced operators.

- Durable and Reliable: Built with a strong frame and high-quality components, the KR-1610D is engineered for long-term performance, ensuring consistent results in commercial and industrial environments.

- Cost-Effective: An affordable solution for businesses and hobbyists that need high-quality engraving and cutting without a large investment in equipment.

Maintenance:

- Regular Cleaning: Clean the laser lens, mirrors, and cutting area regularly to ensure optimal cutting quality and to remove debris that could affect performance.

- Laser Tube Care: Monitor the condition of the CO2 laser tube and replace it when output power starts to diminish to maintain optimal cutting and engraving results.

- Lubrication: Periodically lubricate the moving parts, such as rails, motors, and belts, to ensure smooth and consistent operation.

- Cooling System: Check and maintain the water cooling system to prevent overheating of the laser tube and ensure longevity and efficiency.

- Software Updates: Keep the control software up to date for performance improvements, bug fixes, and compatibility with new design files.

- Component Checks: Regularly inspect electrical components and moving parts to ensure they are in good working condition and replace any worn or damaged parts.

Uses:

- The KR-1610D is suitable for a wide variety of applications, including:

- Signage and Displays: Cutting and engraving detailed logos, signage, and promotional displays from materials such as acrylic, plastic, and wood.

- Home Décor: Creating custom and personalized décor items like wooden frames, wall art, and acrylic photo frames.

- Crafting and DIY: Ideal for crafting hobbyists and small businesses that produce personalized gifts, jewelry, and home decorations.

- Packaging: Cutting and engraving materials for custom packaging, including cardboard, paper, and plastics, for branding and product packaging.

- Advertising: Engraving custom promotional products such as awards, trophies, and corporate gifts.

- Leather and Fashion: Engraving and cutting designs into leather goods such as wallets, belts, and custom clothing.